Variations

Used as Starter & Add-on Sections

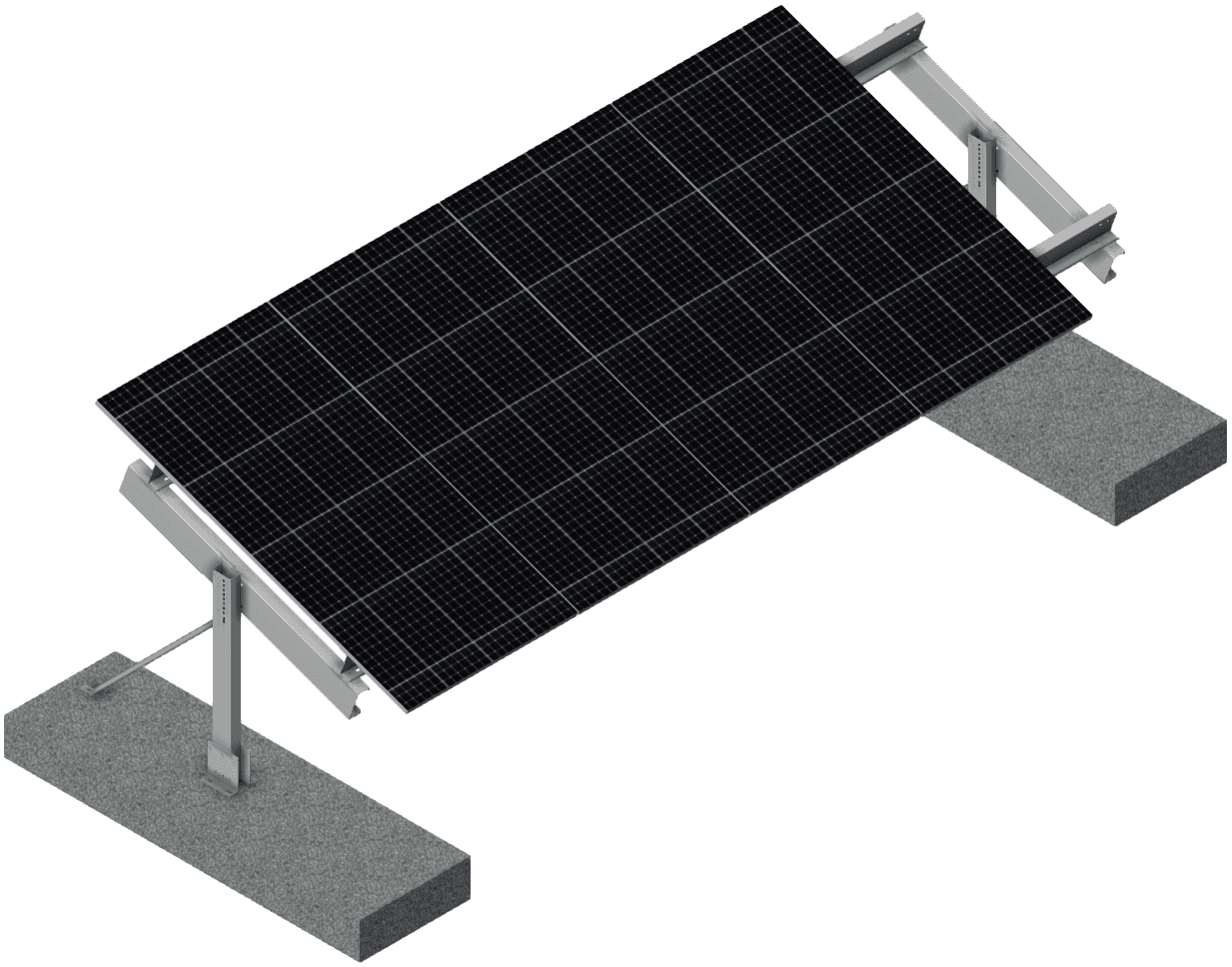

Single Solar Panel high Rows in Portrait Orientation.

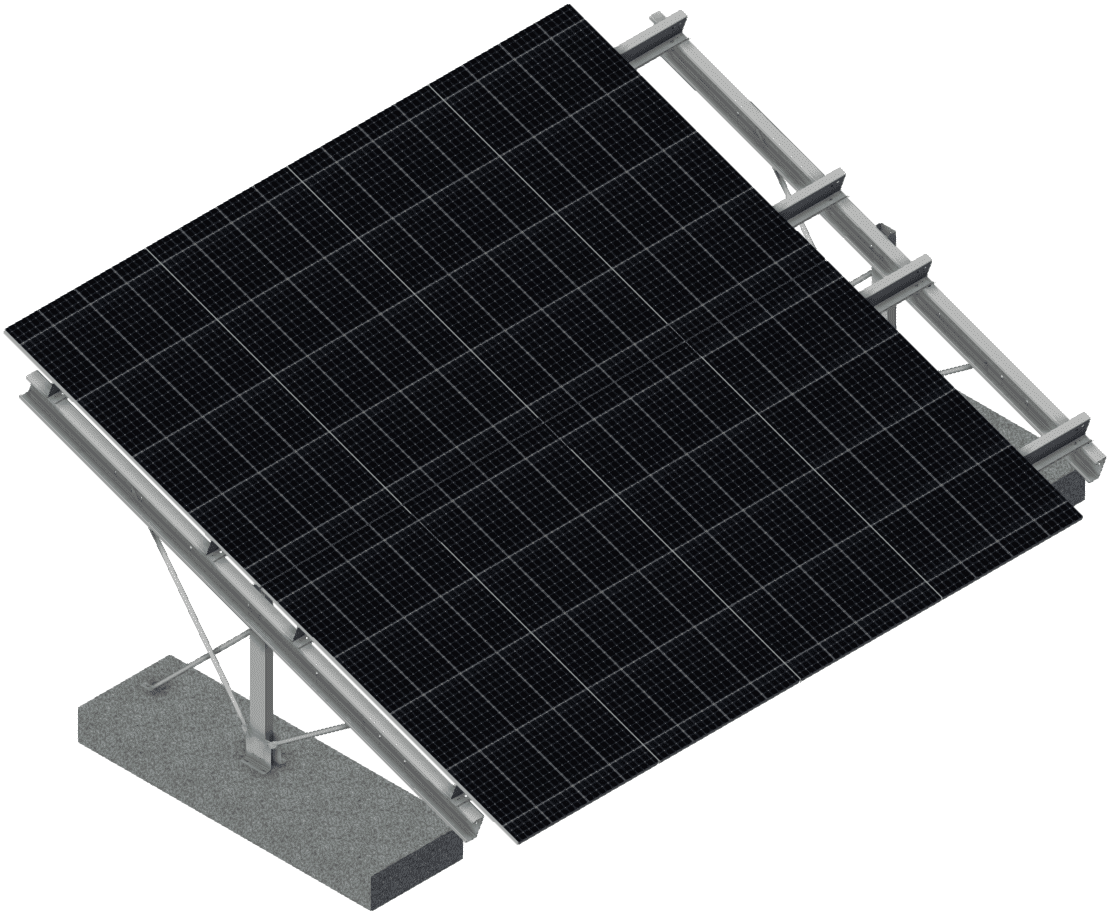

Two High Solar Panel Rows in Portrait Orientation.

Components

View the parts that make up our ballasted ground mounts

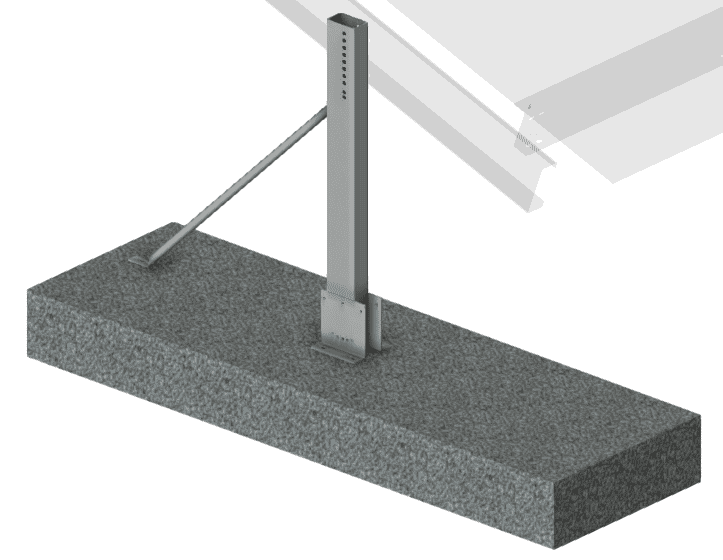

Post

- Pre-Cast Ballast w/ Anchor Bolts & Plates Pre-assembled.

- Patented Articulating & Leveling Post design.

- Telescoping post adapter for rolling elevation.

- Minimal ground PSF design for capped landfills.

- 50 and 80 KSI, G90 and G185 , 11 Gage Steel.

Truss

- Stamped with galvanized coating.

- JS 500 finish mounting hardware

- Fits all solar modules.

- Multiple angle 15°-45°

- 50 and 80 KSI, G90 and G185 , 11 Gage Steel.

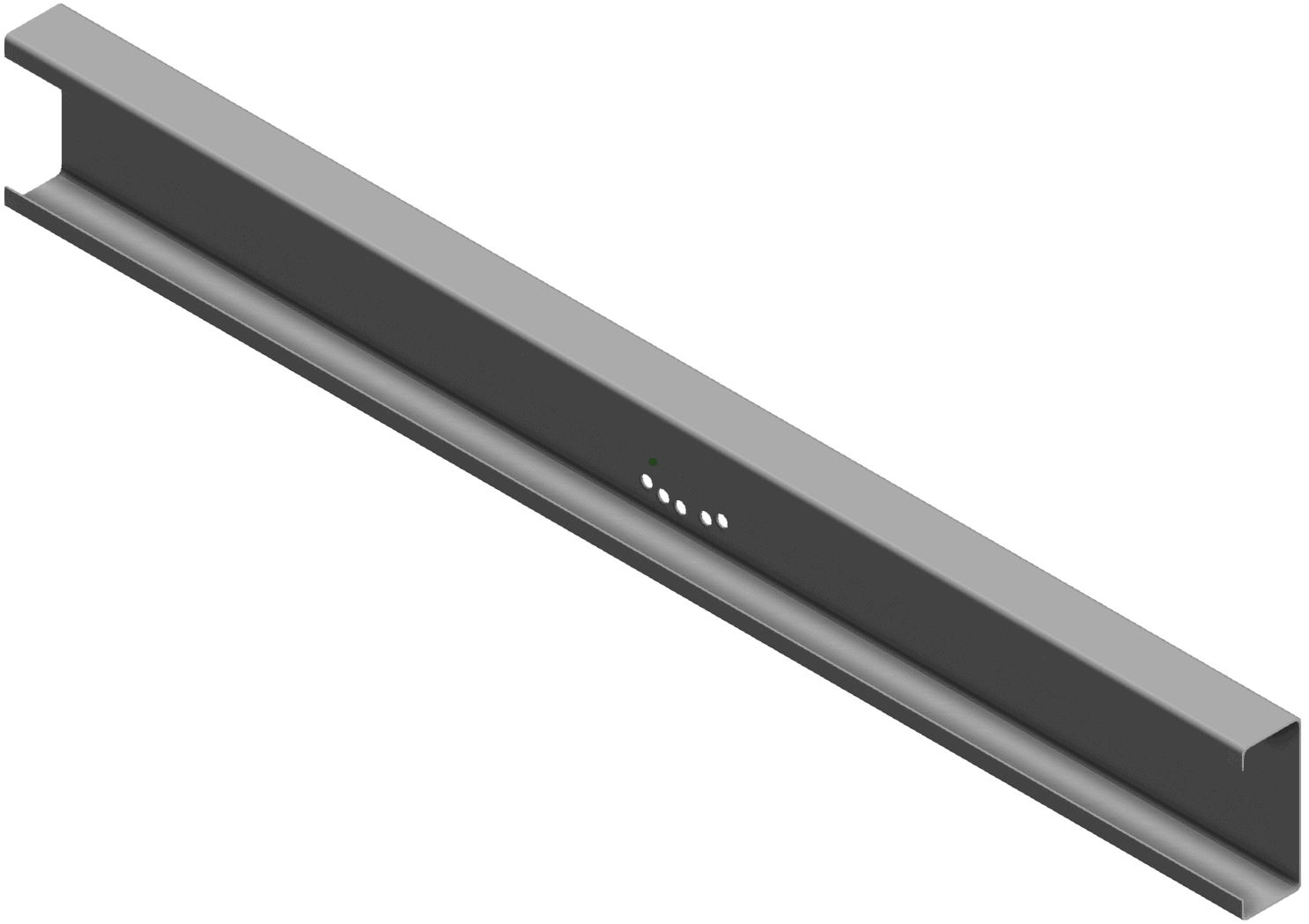

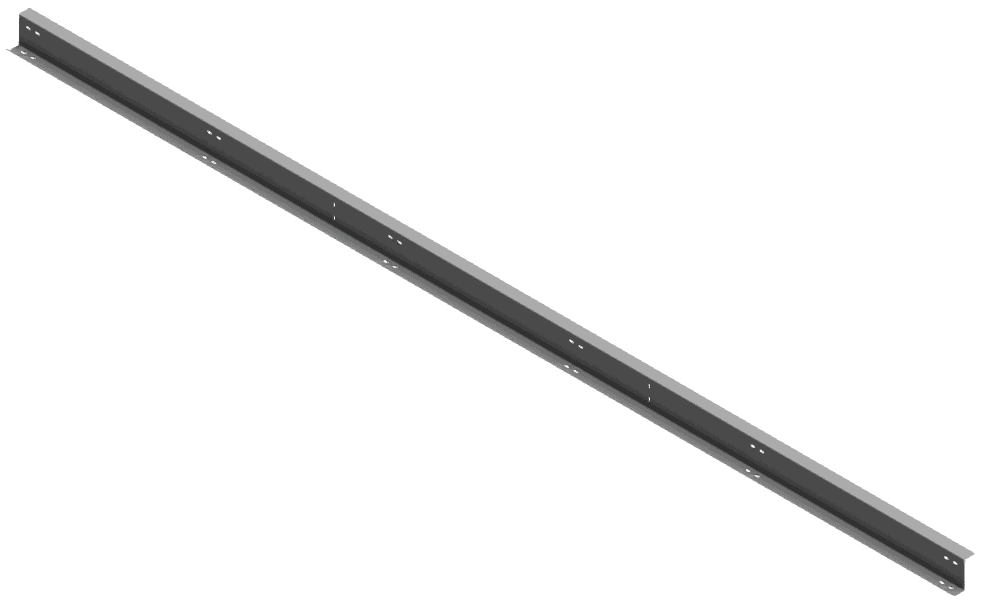

Purlin

- 208″ long with 4″ overlap.

- 204″ Spacing center to center.

- Z Channel profile with top mounting clamps.

- Mounting holes for wire management.

- 50 and 80 KSI, G90 and G185 , 11 Gage Steel.

Pre-Cast Ballasted Advantage

A Versatile Solar Racking Solution for Challenging Terrains and Rapid Installation

Where to Use?

Created from 100% USA steel, manufactured in Michigan, this top tier commercial and utility scale solar racking solution excels in versatility, making it an ideal choice for covering landfills and brownfields. Additionally, it proves highly effective in challenging terrains, including rocky landscapes and mountain regions where standard post driven ground mounts face difficulties. Elevate your solar project with our patented adjustable bolt down system, with dual tilt adjustability.

Made to Stock & Easy Installation

SM’s solar ground mount solutions are meticulously crafted for efficiency and convenience. At SM, we take pride in our commitment to standardization, simplifying our ground mount racking into three main features. This approach allows us to maintain a robust inventory at any given time, providing our clients with unparalleled industry best-lead times. Not only does it get our product to our customers quicker, but the minimal competent design allows for easy installation, with an all bolt together system and no field welding required. Empowering our customers to seamlessly transition to their next project.

In-Factory or Off Site Assembly

At SM we dedicate ourselves to ensuring seamless project experience for our customers, whether we handle the solar racking installation or not. Another advantage of our ballasted system is the pre-assembly of posts and trusses to the block at the factory or SM laydown site, streaming the on-site process to include only purlins and hardware.

Impact On Cost

Labor costs are a significant portion of utility scale solar investment. The precast solar ground mount reduces on-site labor by as much as 1/3. Furthermore, unforeseeable material and labor costs associated with Pour in Place designs often plague the bottom line for EPCs. Precast deliveries completely avoid these unforeseen labor and equipment costs.